Stick Tang Kukri Explained: Myths vs Reality

A practical, experience-driven guide for serious buyers, users, and blade enthusiasts

The stick tang kukri—also known as the rat tail tang—is one of the most misunderstood aspects of the kukri knife. If you search forums or watch short-form videos, you’ll find extreme opinions on both sides. Some call it weak, outdated, and useless; others swear by it for real-world use. After years of forging, repairing, testing, and listening to customers across the US and beyond, I can say this with confidence: most of what’s said about rat tail tang kukris online is either incomplete or completely wrong. Often, these topics are covered under black and white statements, we can say right or wrong; no middle ground, which completely explains the issues and true facts.

This article is written from my experience, not theory. It combines traditional history, modern metallurgy, field usage, and actual repair data from my own kukri house, Himalayan Blades. If you’re planning to buy a khukri or purchase a Khukri online, this guide will help you separate fact from marketing noise—and make a decision you won’t regret. Sometimes, it happens that buyers make the decisions for each penny an item costs. Therefore, it is very important for a buyer to understand everything. If you want to understand about types of tang in a kukri knife, you can refer to the detailed content on this topic.

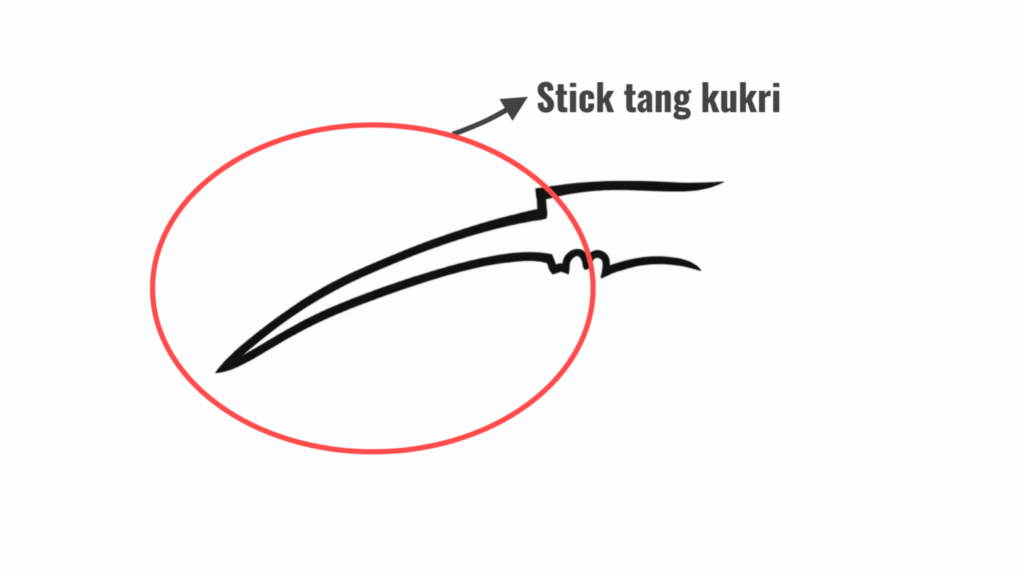

Understanding the stick tang kukri (rat tail tang)

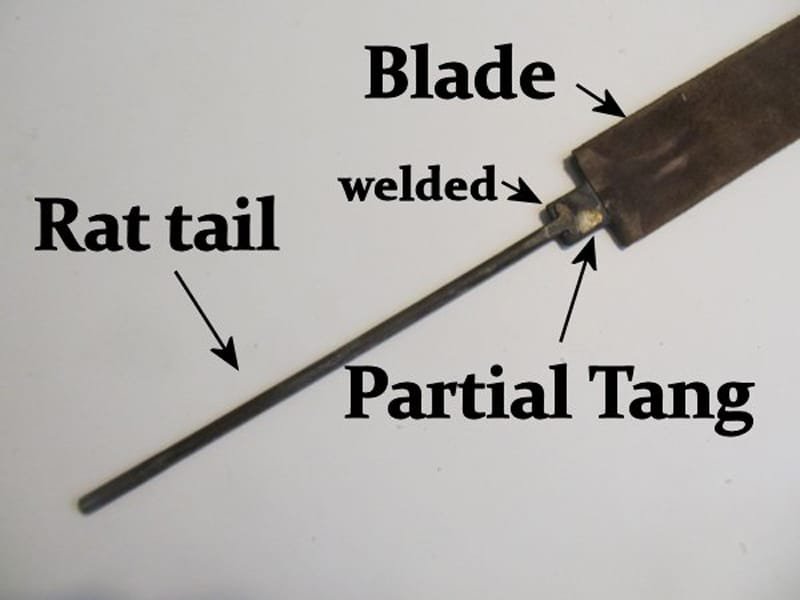

A stick tang kukri is a construction style where the tang narrows as it extends into the handle, rather than occupying the full width of the grip. This tang is forged as a single piece from the same steel as the blade itself. There is no joint, no weld, no separate rod—just a continuous flow of steel shaped by hammer and heat.

The term rat tail tang has gained a negative reputation largely because it has been misused to describe welded tangs; those welded tangs are different (inferior version) of the stick tangs. Unfortunately, many mass-produced kukris blur this distinction, and the reputation of a time-tested design suffers because of shortcuts taken by modern manufacturers.

In traditional Nepali khukuri-making, the stick tang was never a compromise—it was a solution. A solution for balance, shock absorption, ease of re-handling, and long-term usability. Some of the kukris that were originally produced in stick tangs are:- MK1 khukri, Angkhola Khukri, Fast Angkhola, BSI khukri, etc.

A brief historical perspective: why stick tangs existed long before debates did

Long before online debates, kukris were tools of survival and war. Gurkha soldiers, farmers, woodcutters, and hunters depended on them daily. If the stick tang design were inherently weak, it would not have survived centuries of brutal real-world use.

Historically, kukris were:

- Used for chopping hardwood

- Carried on long marches

- Maintained and re-handled multiple times over decades

- Forged without modern adhesives or power tools

The stick tang allowed damaged handles to be replaced without scrapping the blade—an essential feature in remote Himalayan regions. That same practicality still matters today.

Myths vs reality: what people get wrong about rat tail tang kukris

Myth 1: Stick tang kukris snap easily

Reality: Almost every tang failure I have seen—both online and through my own experience as a kukri house owner—involves welded tangs, not forged ones. Welded tangs fail far more often because welding creates a heat-affected zone and a stress concentration point. These are exactly the areas where force should flow smoothly through the steel, but the added rigidity from welding blocks that flow, causing the tang to crack or break under stress.

Myth 2: Full tang automatically means stronger

Reality: It isn’t about how much steel is visible. Strength comes from steel quality, heat treatment, tang geometry, and blade grind. A badly heat-treated full tang is weaker than a properly forged stick tang. In fact, those poorly made full tang kukris often face problems of broken handle material.

Myth 3: Stick tangs can’t handle hard use

Reality: With weight distribution and shock absorption, the stick tang kukris will likely be more suitable for extended periods of chopping. Less shock is transferred to the hand and handle, which reduces fatigue and prevents cracking. I have posted many videos on our YouTube channel showing extreme chopping tests of stick tang kukris.

Myth 4: Rat tail tangs are outdated

Reality: They’re still widely used because they work. Tradition survived because it performed, not because it looked good in photos.

Materials and metallurgy: where quality really lives

Whether you’re evaluating a kukri knife in hand or deciding to purchase Khukri online, focus on these factors:

- Steel selection: High-carbon steels like 5160 or similar spring steels excel due to toughness and elasticity.

- Heat treatment: Differential hardness between the blade and the tang is intentional. A slightly softer tang absorbs shock rather than transferring it.

- Tang taper: A forged taper distributes stress gradually instead of concentrating it.

- Handle fitment: Poor fit causes micro-movement, which leads to cracks—not tang failure.

At Himalayan Blades, tangs are forged—not welded—and heat treated as part of the blade, not as an afterthought.

Our Data: what 3 years of real repairs reveal

This is where experience matters more than opinion.

Over the last three years, we tracked kukris sent to us specifically for handle or tang-related repairs in the stick tang category. The results were revealing:

- 65% of failed stick tang kukris had welded tangs

- These welds caused uneven force distribution

- Failures included:

- Tang breakage at the weld joint

- Severe shock transfer cracking of handle materials

- Handles loosening beyond repair

Most of these kukris came from local makers, cutting costs or mass production businesses focused on volume rather than integrity.

At Himalayan Blades, each khukuri is meticulously forged based on individual customer customisation. We do not—and cannot—operate on a mass-production model.

Each kukri model can be configured in 972 different combinations (handle materials, lengths, sheaths, finishes, tang styles, and more). As of January 2026, we offer 20 core models.

- Stocking just one of each configuration would require 19,440 unique kukris

- Maintaining even a minimal inventory of 20 per configuration would mean 388,800 pieces

- That is logistically impossible and economically illogical

This is why we forge on orders—and why our focus stays on quality, not shortcuts.

Poor Examples of Stick Tang Kukri (What to Avoid at All Costs)

Not all stick tang kukris are made the same. In fact, most failures blamed on “rat tail tangs” come from poor workmanship, not from the tang design itself. Over the years, while inspecting and repairing damaged kukris, two dangerous patterns appear again and again. I have talked about the types on tang here.

Poorly welded stick tang

This failure is one of the most common and most dangerous we encounter. In these cases, the maker welds the tang poorly—the weld remains incomplete, uneven on all sides, or already shows visible cracks.

Under moderate to heavy stress, the tang breaks inside the handle. At first, the kukri still appears usable because friction keeps the blade and handle aligned. That false alignment creates a dangerous sense of safety. As soon as the user applies more force, the remaining resistance suddenly gives way, and the blade slings out of the handle while the handle stays in the user’s hand.

At that point, the kukri becomes more dangerous to the user than to the task. The blade can injure the user or anyone standing nearby. This is not a rare accident—it is a predictable failure caused by poor welding.

Welded tang at the wrong angle

Another critical failure occurs when a maker welds the tang at an angle that does not match the natural anatomy of the kukri.

A kukri is designed so that force flows in a specific direction during chopping and cutting. When the tang angle does not align with the blade’s anatomy, the force fails to distribute evenly. This imbalance places excessive stress on one side of the handle.

As a result:

- Handle materials such as buffalo horn or Indian rosewood that crack prematurely

- The handle loosens much faster than it should

- In severe cases, the blade slings out of the handle and causes injury

We have seen multiple examples of tangs welded at visibly incorrect angles, and these failures do not happen by accident—they occur because of a poor understanding of kukri anatomy.

The Perfect Anatomy of a Stick Tang Kukri

The maker hammers and pinches the tang, never welding it. In a true stick tang, the kukri remains a single piece of steel, carefully slotted and shaped to the exact length of the handle, then balanced and aligned evenly from every side.

The tang section is often left slightly softer than the rest of the blade. This is intentional. A softer tang absorbs vibration and impact, spreading shock over a wider area instead of driving it straight into the handle.

Most importantly, the angle of the tang follows the natural curve of the kukri. This alignment allows force to flow smoothly through the blade without concentrating stress in any one point. As a result, the kukri stays safe and predictable even during extended, demanding use.

This is not weak engineering. This is smart, experience-backed engineering, refined over generations for a reason.

Stick tang vs welded tang: the difference buyers must understand

This distinction cannot be overstated.

- Forged stick tang: One piece of steel, gradual taper, shock absorption

- Welded tang: A Separate rod joined by a weld, a stress point, and failure-prone

If a seller avoids answering whether the tang is welded, that’s your answer.

Real-world use cases: survival, martial arts, and self-defence

Here it is rewritten into active, clear pointers with a strong human tone:

- For survivalists: A stick tang kukri delivers powerful chopping while keeping fatigue under control, even during long sessions in the field.

- For martial artists: The balanced weight and responsive handling allow faster recovery and cleaner transitions between strikes and movements.

- For self-defence-minded users: Reliability matters more than looks, and a properly forged stick tang kukri performs exactly as it should when stress is real.

- For blade enthusiasts: Understanding how a kukri is built turns collecting from simple display into true appreciation.

Buying advice: how to safely buy a khukri online

Before you commit:

- Ask if the tang is forged or welded

- Ask about heat treatment, not just steel type

- Look for real usage photos, not just studio shots

- Choose makers who talk openly about repairs and failures

Transparency is not marketing—it’s accountability.

Final thoughts: reality over reputation

The rat tail tang kukri is not weak; poor craftsmanship is.

When forged correctly, a stick tang kukri delivers strength, resilience, and easy repairability, all backed by centuries of real-world use. At HimalayanBlades.com, we don’t chase trends; we forge tools meant to be used, trusted, and passed down.

If you want a kukri that truly reflects tradition, performance, and honest craftsmanship, take your time. Ask the right questions. Learn what you’re buying.

A kukri is not just a blade—it is a responsibility.

And if you want help choosing the right configuration or understanding which tang style fits your needs, that conversation is always open.