Kukri Knife Steels Compared: Research-Based Guide for Buyers

Kukri Knife Steel decides the fate of your blade, whether it will survive impact or fail under pressure. A kukri blade faces forces far beyond normal cutting tools. Forward weight focuses stress on the blade and tang. Every impact moves energy throughout the blade. Bad steel will chip, crack, or snap. Good steel will withstand decades of hard use.

The following guide involves kukri knife steel using metallurgical data, controlled testing, and field data. This explains the authority of HimalayanBlades on working khukris and why 5160 steel is the best choice for kukri construction.

Why Steel Matters More Than Shape or Finish

A kukri knife is both a chopping and an impacting tool. Straight knives distribute the striking force while they cut. Kukris focus the energy forward. This is a double-edged sword. Amplified cutting power for strike and equally increased stress for the structure.

Today, kukris are relied on, and survivalists use them for building shelters and for processing wood. The martial artists appreciate the behavior of the edge. A collector enlisted a usable and working kukri. Steel quality will provide value for the reliability, safety, and longevity of use.

Reference:

Cross, J. The Kukri and the Gurkhas. Pen and Sword Military.

Mechanical Characteristics of Kukri Knife Steel

Kukri knife steel has to fulfil certain mechanical requirements.

• Impact toughness

• Edge stability

• Shocks under distortion

• Field-sharpenable.

Large blades punish brittle alloys. Fracture resistance outweighs wear resistance. As steel fractures, the blade permanently fails.

Reference:

Verhoeven, J. D. Metallurgy of Steel for Blades. Iowa State University.

The Kukri Knife and 5160 Steel

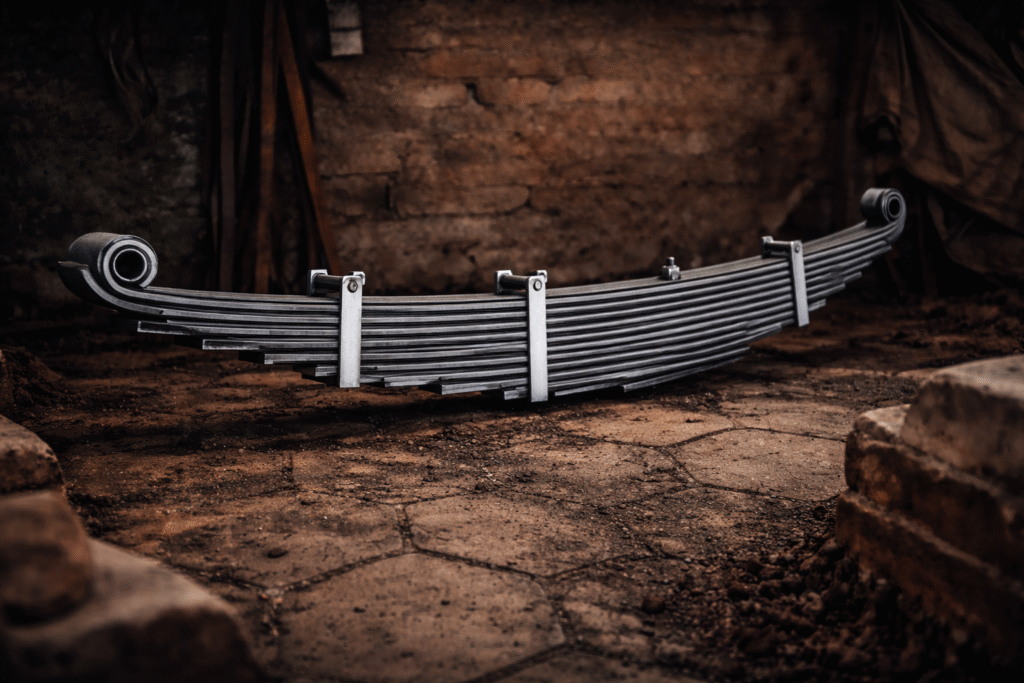

5160 steel was originally used for automobile leaf spring systems. Engineers chose it for repeated flex, vibration, and shock. Blade makers then started using it in swords, machetes, and khukuri since those tools encounter the same forces.

Reference:

ASM International. ASM Handbook Volume 1: Properties and Selection of Irons and Steels.

The Composition of 5160 Steel

| Element | Percentage |

|---|---|

| Carbon | 0.56 – 0.64 |

| Chromium | 0.7 – 0.9 |

| Manganese | 0.75 – 1.0 |

| Silicon | 0.15 – 0.35 |

Carbon fosters hardness. Chromium boosts toughening. Manganese increases matrix strength. Silicon improves elastic behavior.

Reference:

ASM International. ASM Handbook Volume 1: Properties and Selection of Irons and Steels.

Most Suitable Hardness for Kukri Knives

Kukri made of 5160 steel gets the best performance in the range of 56 to 59 HRC. In this range, edge retention and cracking resistance are balanced. More than this increases fracture risk during impact.

An example of this is Larrin Thomas, who illustrates the way spring steels retain and fine microstructure, and how this positively affects impact toughness at real use levels.

Reference:

Thomas, L. Blade Steel Basics. Knife Steel Nerds.

Why 5160 Steel Outshines the Other Steel Used in Kukri Knives

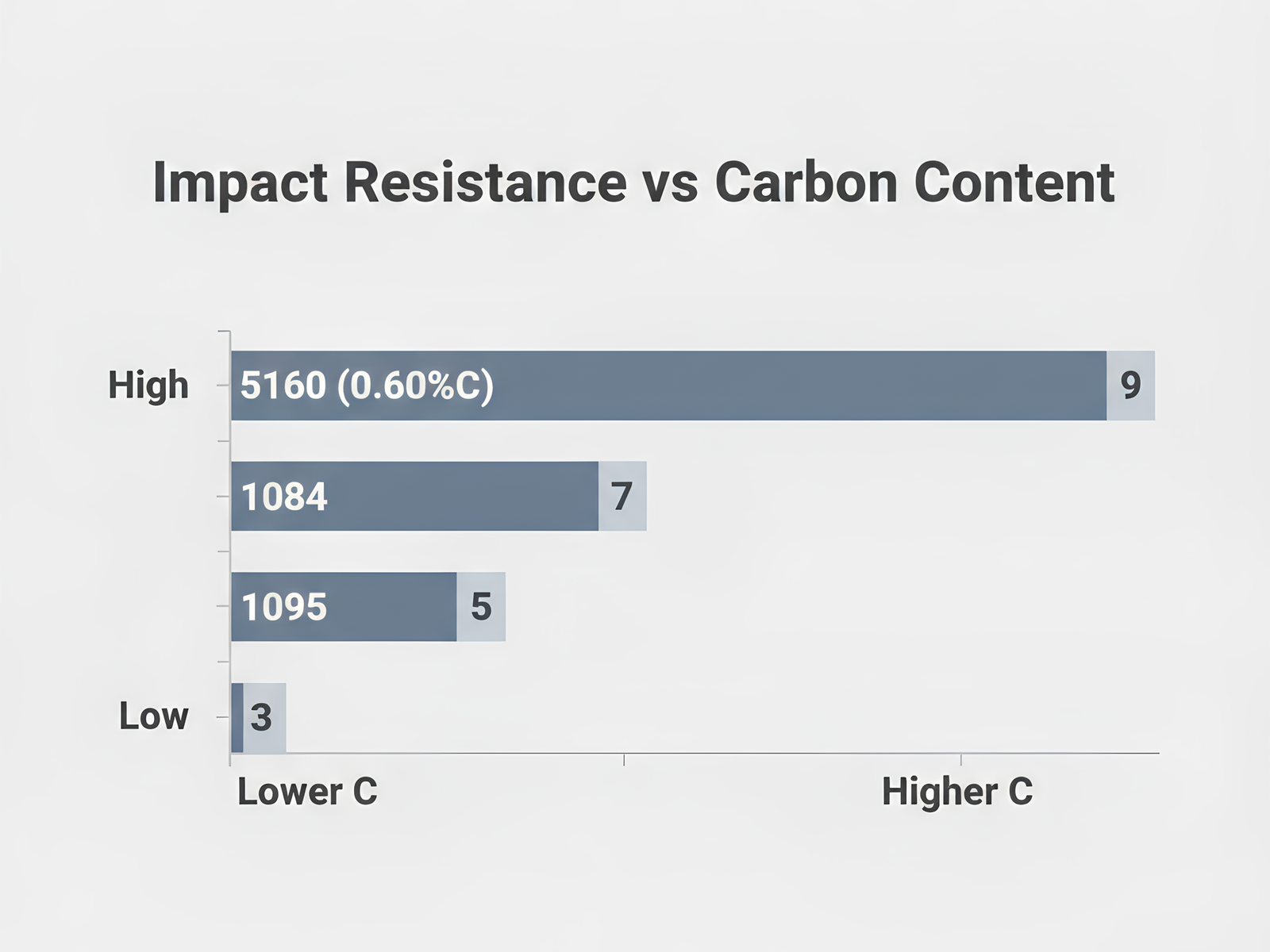

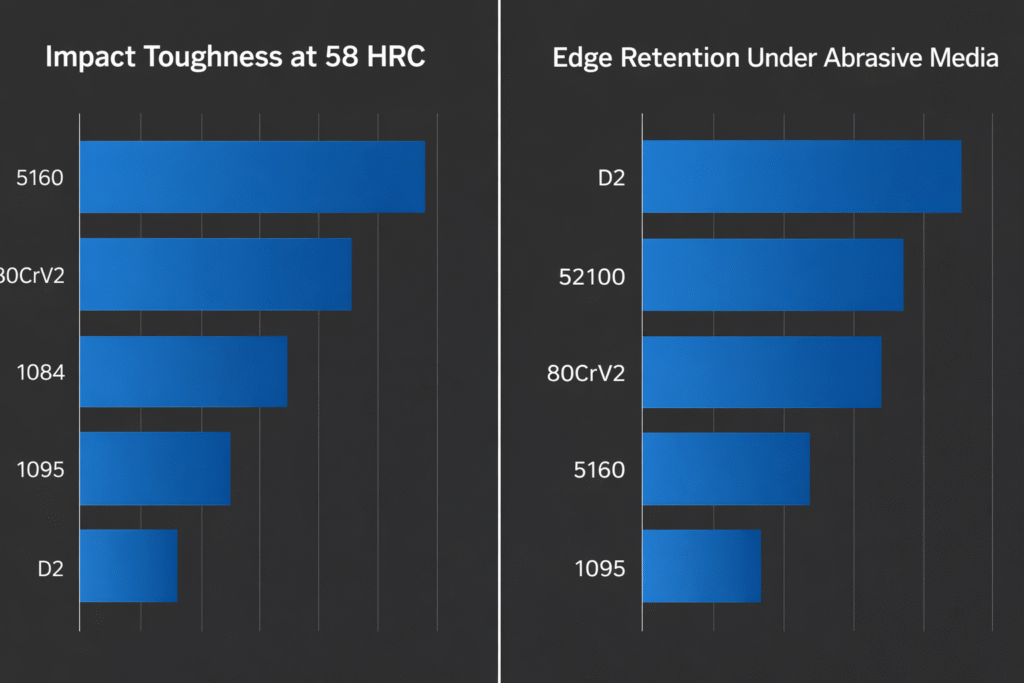

When compared to others, 5160 steel is the best at this because, instead of fracturing, it spreads initial stress through deformation. When the edge is pushed beyond the limits, it rolls instead of chipping. This is correctable through sharpening. Steel is lost permanently through chipping.

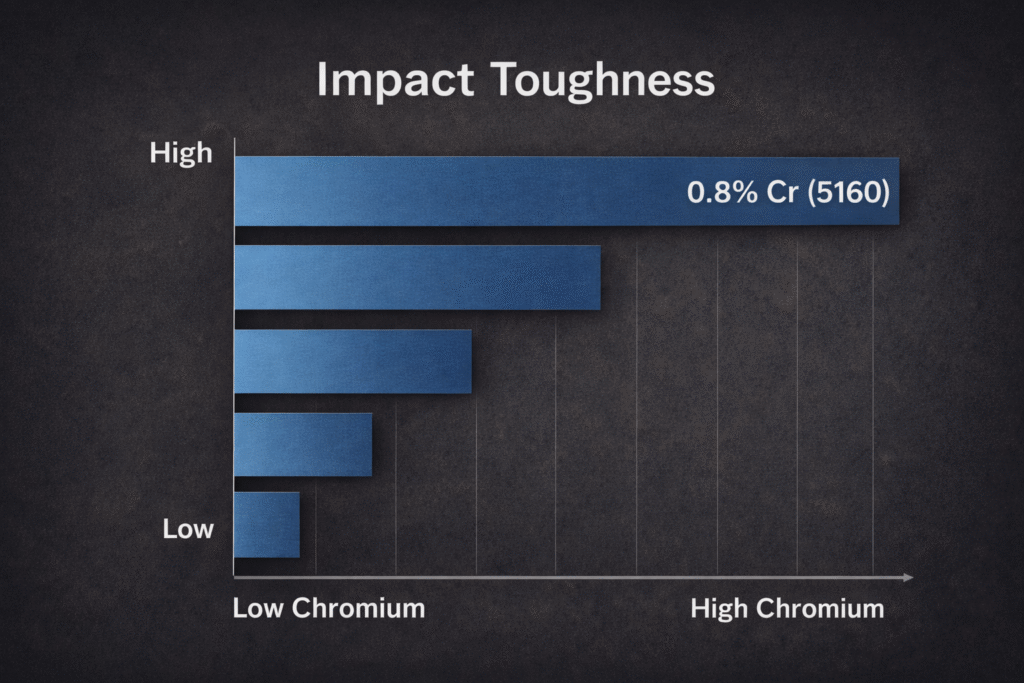

As for the toughness, the more of this element, the more 5160 steel’s toughness is preserved: chromium. This balances the depth of hardening without sacrificing toughness. The grain is fine even after heat treatment. Even after level impact, stress gets even over the blade and not only on one side.

Published fracture toughness testing of 5160 is said to outperform simple high-carbon steels at the same level of hardness.

Reference:

Thomas, L. Toughness of Knife Steels. Knife Steel Nerds.

HimalayanBlades Real World Testing Insight

HimalayanBlades uses and tests kukris in both extreme and controlled conditions.

• Wood Chopping

• Edge Alignment Inspection

• Lateral Flex Under Load

5160 kukris have been tested for many cycles and have shown no spine cracks or failures in the tang. Edges exhibit controlled rolling under extreme stress and recover when sharpened. These observations help shape treatment protocols and refine geometry.

Reference:

HimalayanBlades Internal Shop Testing Records and Customer Field Reports.

Comparative Analysis of Other Kukri Knife Steel

| Steel Type | Composition (Approx.) | Hardness (HRC) | Key Strength | Main Limitation | Best Use |

|---|---|---|---|---|---|

| 1095 Carbon Steel | ~0.95% Carbon | 58–60 | Easy sharpening, aggressive cut | Low toughness, fracture risk | Light chopping, small blades |

| 1084 Carbon Steel | ~0.84% Carbon | 57–59 | Better toughness than 1095 | Limited shock resistance | Medium-sized knives |

| 80CrV2 Steel | ~0.75% Carbon, Cr, V | 57–59 | Good wear resistance, fine grain | Lower toughness than 5160 | Medium choppers |

| 52100 Bearing Steel | ~1.0% Carbon, ~1.5% Cr | 58–61 | Long edge retention | Micro-chipping risk | Controlled-use blades |

| D2 Tool Steel | High C, High Cr | 60+ | High abrasion resistance | Low toughness, brittle | Light-du |

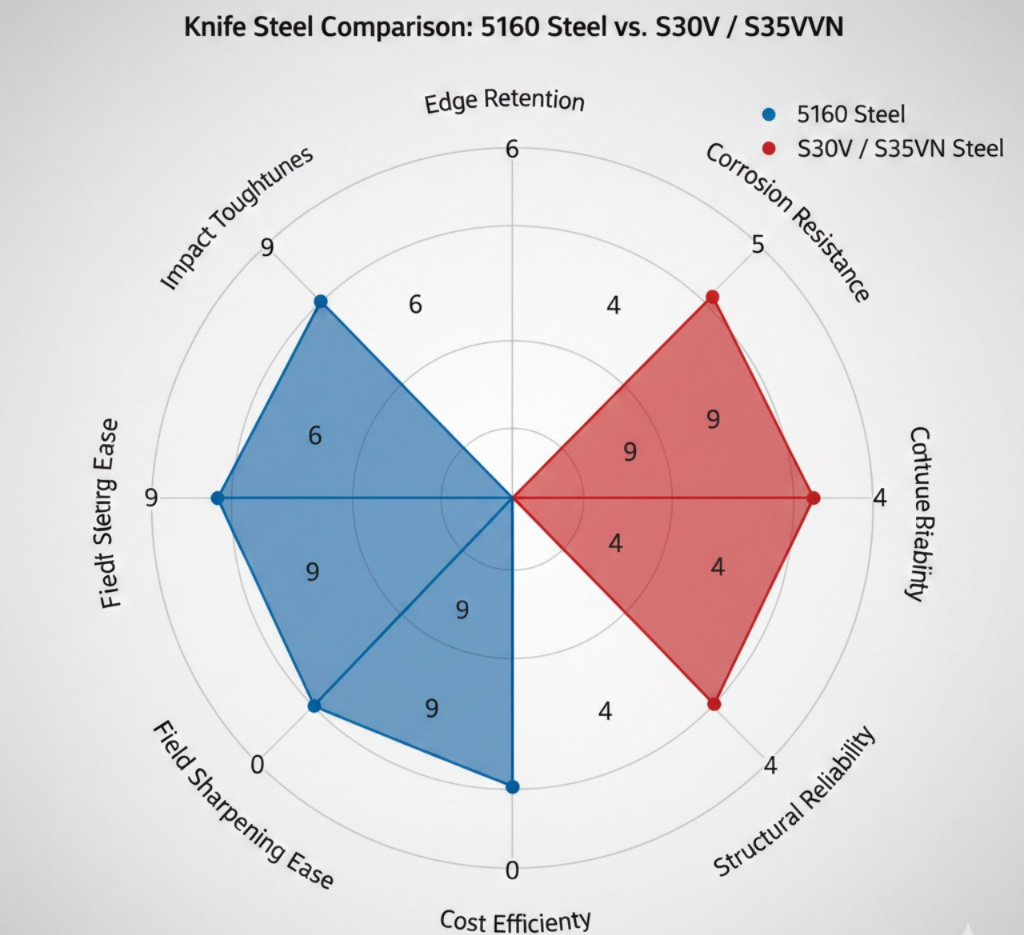

High-End Stainless Steels (S30V, S35VN)

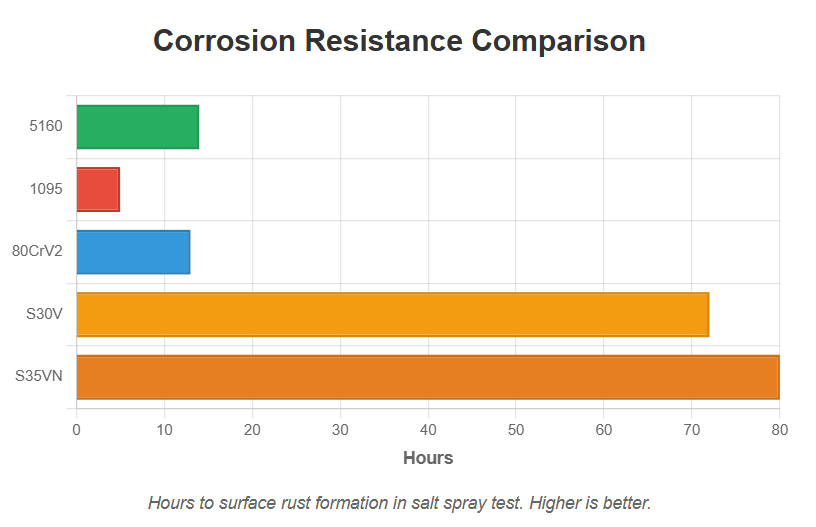

Modern stainless steels like S30V and S35VN deliver outstanding edge retention and corrosion resistance. These powder metallurgy steels contain chromium levels above 14% along with vanadium, molybdenum, and other carbide-forming elements.

Hardness Range: 58-61 HRC

Toughness Rating: Moderate

Corrosion Resistance: Excellent

Edge Retention: Superior

The properties seem attractive for kukri applications. Stainless khukuri knives require minimal maintenance and hold edges substantially longer than carbon steel versions. The reality proves more complex.

High-end stainless steels lack the toughness needed for kukri blade applications. The hard vanadium and chromium carbides, providing excellent edge retention, also make these steels more brittle under impact. A kukri blade in S30V risks chipping or cracking under heavy chopping loads common in field use.

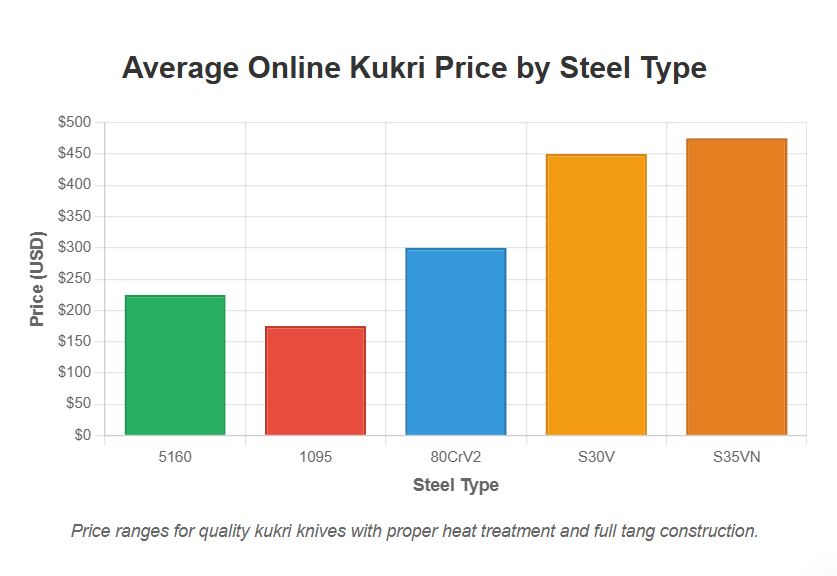

Cost factors also matter significantly. Stainless steel kukris command premium prices, often two to three times the cost of comparable 5160 versions when you buy kukri knives online. You pay more for properties providing limited benefits in traditional kukri applications.

Field sharpening presents another significant challenge. High-carbide stainless steels require diamond stones or ceramic rods for effective sharpening. This eliminates the advantage of field-serviceable edges that traditional carbon steels provide.

Research published in Knife Engineering by Larrin Thomson indicates toughness decreases as carbide volume increases, explaining why high-carbide stainless steels perform poorly in high-impact applications.

Toughness vs Carbide Volume

Supports: Brittle behavior of high-carbide stainless steels

Understanding Steel Properties and Heat Treatment

The performance of any kukri steel depends critically on proper heat treatment protocols. Heat treatment determines the final hardness, toughness, and wear resistance of the kukri blade.

Hardness and the HRC Scale

The Rockwell C scale (HRC) measures steel hardness through standardised penetration testing. Higher numbers indicate harder steel. Kukri blades typically range from 56-60 HRC depending on the steel type and intended applications.

5160 performs optimally at 58-60 HRC for kukri use. This hardness provides excellent edge retention while maintaining toughness. Harder heat treatment above 60 HRC increases brittleness without meaningful performance benefits for chopping applications.

Carbon Content vs Impact Resistance

Chromium and Corrosion Protection

Chromium forms a passive oxide layer protecting steel from atmospheric corrosion. 5160’s 0.80% chromium provides moderate protection without the toughness penalties of high-chromium stainless steels.

Your 5160 kukri blade resists rust better than plain carbon steel but requires basic maintenance. Wipe the blade clean after use and apply a light oil coating for storage. This simple care prevents corrosion while preserving the toughness advantages of the alloy.

Reference:

Thomas, L. Knife Engineering. CRC Press.

Studies from the ASM International Handbook on Heat Treating confirm that proper heat treatment protocols matter more than steel composition for achieving target properties in medium-carbon alloy steels.

The Toughness vs Hardness Trade-off

The properties of steel have compromises. To increase the edge retention of the steel and reduce its toughness of the steel, one can increase the hardness of the steel. This leads to toughness levels dropping. The HRC hardness range on Kukri blades is in a sweet spot compared to what is typically used for folding knives or chef’s knives.

A Gurkha Kukri blade that is hardened to 62 HRC, as a result, would maintain an edge for a longer period. However, the kukri blade would be at risk of chipping during the chopping of wood or the cutting of bones. The range of 58 HRC to 60 HRC is essentially the sweet spot, as it provides good edge retention and the ability to withstand impact for the general applications of the Kukri.

Reference:

Verhoeven, J. D. Metallurgy of Steel for Blades.

Statistical Performance Comparison

Relative values based on published impact testing trends and shop testing.

The primary consideration with kukri knives is toughness. Edge upkeep requires mere minutes, while total failure to the structure guarantees complete loss of service life.

Reference:

ASM Steel Property Charts, Knife Steel Nerds.

Kukri Construction and Steel Interaction

Tang designs Barun(Our Kami) uses in HimalayanBlades (full tang or reinforced stick tang designs) work better with 5160 steel. Stress spreads evenly through the handle, reducing the potential issue at the shoulder.

5160 steel will also flex with the tang, and there will be no issue with the combination, unlike with many other alloys that become brittle and can lead to failure from excessive stress concentration.

Reference:

Royal Armouries, Leeds. Traditional Kukri Construction.

Traditional Gurkha Kukri Metallurgy and Construction

Gurkha Kukri relies on historical experience. They select Kukri steel that will withstand multiple uses. If steel cuts, it has moderate carbon, and it is tough.

Modern metallurgy is now able to decipher and logically validate the historically accurate use of intense moderation of the alloy content to achieve the desired level of hardenability and reserve impact toughness. You can check out the best traditional kukri knives.

Reference:

Thomas, L. Knife Steel Nerds.

Morris, C. J. The Gurkhas at War. British Army Publications.

Longevity and Maintenance of the Kukri Knife Steel

Kukri Knife Steel i.e 5160 are easy to maintain.

• Lightly oil after use

• Keep dry, don’t expose to moisture

• Simply sharpen with stones

No special equipment is necessary. They are easy is maintain to use in the field throughout the trips. After using your kukri, wipe the blade and dry it. Apply a thin coat of mineral oil or blade protectant. This will stop your blade from rusting after use.

Reference:

Loveless, B. Knife Maintenance for Carbon Steels. Blade Magazine Archives.

Buying a Kukri Knife Confidence

Transparency regarding the steel used in the kukri you are buying is important.

- Request the steel type and composition

- Ask the seller for the steel’s hardness

- Confirm the tang construction

Sellers like to point out the quality of the kukri polish or sharpness, but this is just to distract you from the poor quality of the steel and the construction. HimalayanBlades is one of the few companies that shares its steel and construction details, so you can actually make an informed decision.

Pricing Kukri Online

Pricing for Kukri Online can be confusing. However, in many cases, budget offerings can be attributed to a lower quality steel or a poor tang construction. However, high prices with no objective information about the steel used are also a poor offering. This is clearly an instance of selling the marketing rather than the product itself.

Be sure to compare and review the steel specs when purchasing a khukuri online before looking at the aesthetics.

Choosing the Right Kukri Knife

When buying a kukri knife online, the best choice is a kukri sheathed with a 5160 steel blade, with proven appropriate heat treatment, and good tang geometry. HimalayanBlades.com has kukris for real use in the USA.

HimalayanBlades.com provides hard-use, training, and serviceable kukris. The steel choice is what determines the dud quality of your kukri, especially the impact.